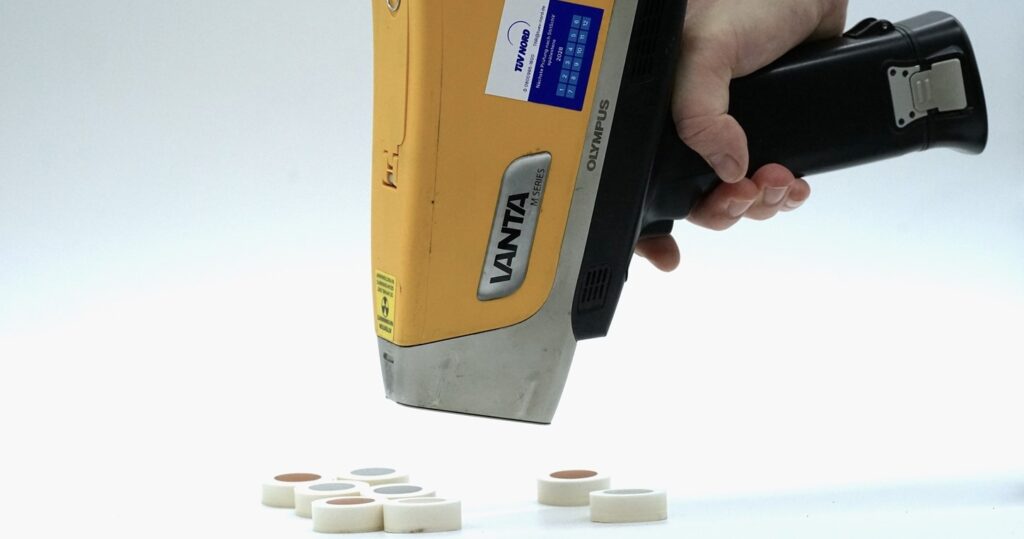

During the Geoanalysis conference in Freiberg in 2022 we met a representative from Evident Scientific (formerly Olympus). Having had a conversation about a potential collaboration and the possibility of loaning a handheld x-ray fluorescence (XRF) instrument we set out to develop a new type of pressed pellet.

Usually, we nano-mill all our samples to make them applicable to microanalytical instruments such as LA-ICP-MS and micro-XRF. For portable XRF the particle size is less of an issue and both available CRM powders and industrial sample powders are in the same approximate range of particle sizes (63-75 µm).

The newly developed pressed pellets have an outside diameter of 32 mm, a sample diameter of 20 mm and a thickness of 10 mm. The thickness is necessary to ensure, that the incident x-rays do not go through the sample, which would yield erroneous results. Having successfully made the minimal viable prototypes we contacted Evident and within a week we had the instrument up and running. The Instrument is the Evident Scientific Vanta XMR. The measurement mode was the GeoChem setup, which employed a 3-beam fundamental parameter quantification. Beam number 1 was 40 kV for 120 seconds, Beam 2 was 10 kV or 60 s and beam 3 was 50 kV for 60 s. The respective elements measured on each beam are as follows:

Beam 1 (40 kV): Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, As, Se, Rb, Sr, Y, Zr, Nb, Mo, Ag, Cd, Sn, Sb, Ba, W, Hg, Pb, Bi, Th, U, LE

Beam 2 (10 kV): Mg, Al, Si, P, S, K, Ca, Ti, Mn

Beam 3 (50 kV): Ag, Cd, Sb, Ba, La, Ce, Pr, Nd, LE

Below we show you some of the results of the tests in the form of graphics and short explanatory texts. If you would like a more detailed insight into the data or are interested in further graphics for other elements, just get in touch with us.

Click HERE to see the current portfolio of pressed pellets.

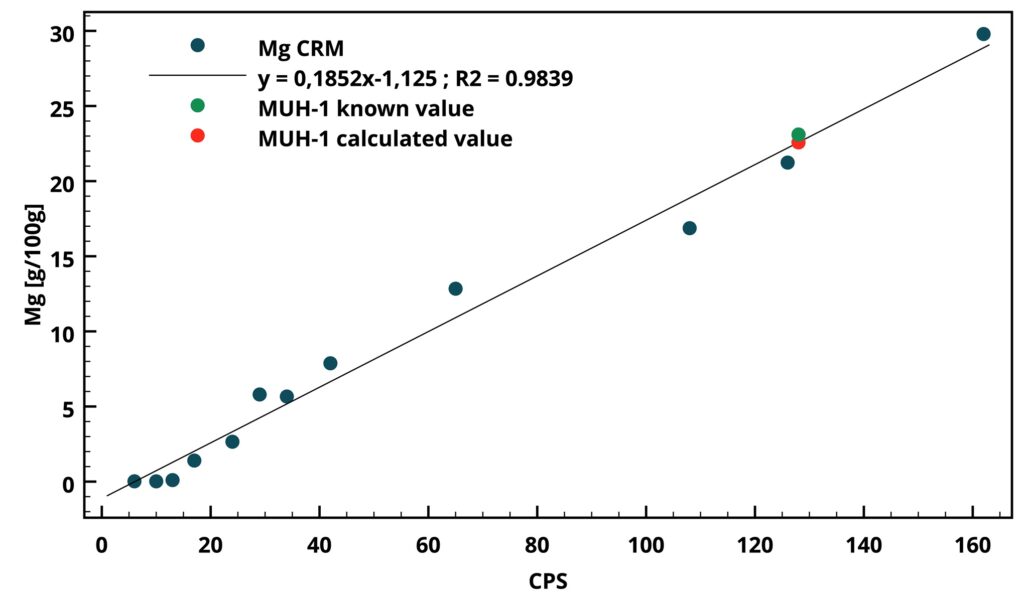

Magnesium Calibration Curve

Using 12 different lithogeochemical certified reference materials and raw instrumental spectral data a calibration curve for magnesium (Mg) was calculated and validated using a 13th material, which was not part of the calibration curve. The x-axis shows the detector signal in counts per second (CPS) and the y-axis the corresponding Mg concentration in g/100 g. Generally speaking, XRF analyses of light elements on loose powders can often be inaccurate to their impeded fluorescence yield. Pressed pellets can help to mitigate this effect, as showcased by an excellent correlation coefficient of 0.984. Further, the calculated value matches the known value of the CRM showing excellent accuracy. The known and calculated values are 23.1 and 22.6 g/100 g respectively, yielding an accuracy of 97.8 %, without considering the values’ uncertainties. Each data point is an average spectrum comprised of four measurements, after each individual measurement the sample was rotated by 90°.

The following CRM were used as pressed pellets to build the calibration curve, the exception being MUH-1, which was used to validate it: AC-E (Granite), BE-N (Basalt), BIR-1a (Basalt), CHR-Pt+ (Chromitite), DTS-2b (Dunite), DR-N (Diorite), ECRM 752-1 (Limestone), ECRM 782-1 (Dolomite), GH (Granite), OREAS 20a (Granodiorite), PM-S (Microgabbro), UB-N (Serpentinite) and MUH-1 (Harzburgite)

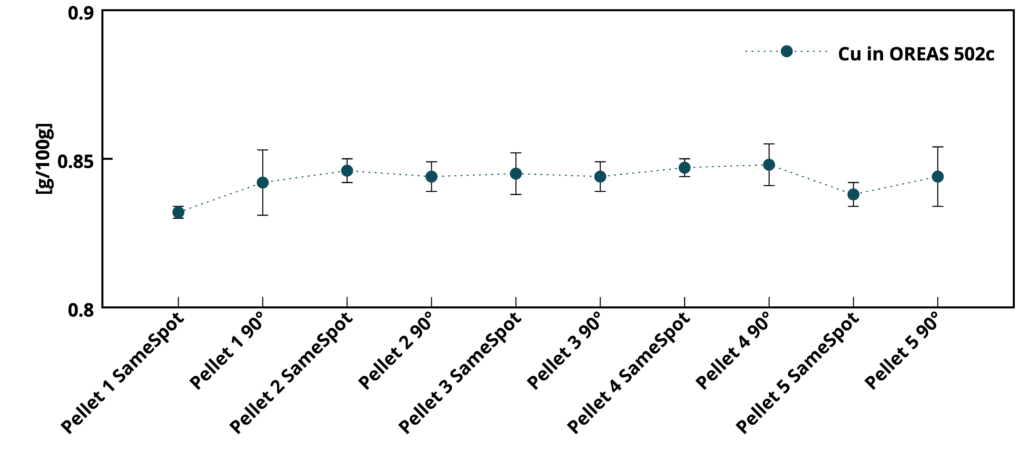

Homogeneity Test

A homogeneity test comprised of five pressed pellets made from OREAS 502c was performed. Each pellet was measured four times in the same spot and four times while rotating the sample 90° between each measurement. The results show excellent within- and between pellet homogeneity. The error bars are 2 SD of the four aforementioned measurements.The graph shows the homogeneity as an example for copper.

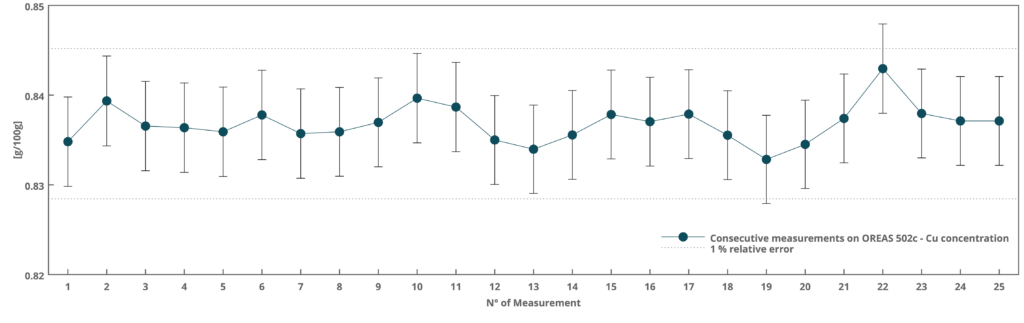

Single Pellet Long Run

This plot shows the results for Cu of 25 consecutive analyses on a single pressed pellet made from OREAS 502c. The analysis time for each data point was 4 min. and the error bars indicate the 3 SD given by the instrument. This displays excellent instrument stability, as the data points are statistically indistinguishable as well as pressed pellet stability during repeated x-ray irradiation.

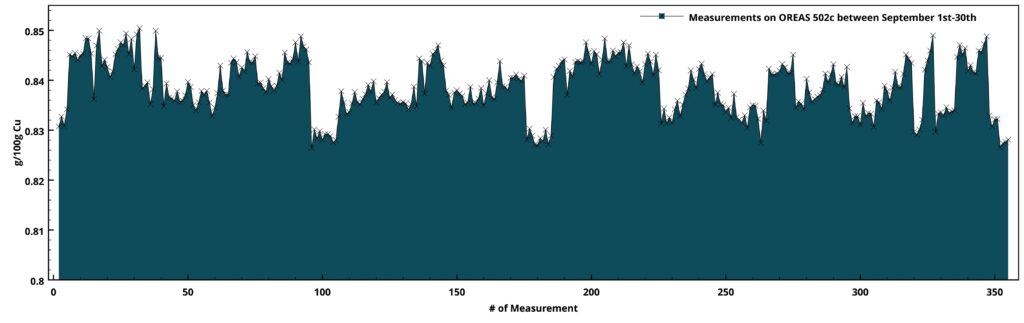

Five Pellets Long Run

This plot shows all 355 measurements performed on five different pressed pellets made from OREAS 502c between September 1st and 30th 2023. The results for copper (Cu) varied between 0.83 to 0.85 g/100 g meaning a deviation of only 0.2 g/100 g. Additionally, this highlights within and between pellet homogeneity and stability during repeated use as well as instrument stability.

Merry Christmas and a Happy New Year!

As we almost close the curtain on this year, we extend our gratitude for a fantastic working relationship. Despite numerous challenges, 2023 has been a rewarding and successful journey for us. As a token of appreciation, we’d like to express our thanks with a special discount code just for you. With this code you will receive 10% off your entire shopping cart when you place an order in December or January on www.my-standards.com:

myChristmas2023

Copy the code and add it to the shopping cart. Valid until 31 January 2024!

Wishing you a delightful Christmas season and a prosperous start to 2024. We eagerly anticipate the opportunity to collaborate with you once again in the coming year!

Latest news posts:

- How to Build Your Custom Pressed Pellet Set for XRF (32 mm)

- An exciting new project: the development of a Sulphide-Nano-Pellet as a reference material

- 32 mm Pressed Pellets for XRF – an alternative to the Nano-Pellets for XRF!

- New certified reference material from biotite: BTNO-Nano-Pellet

- Muscovite certified reference material: MSNA-Nano-Pellet